|

Videos Taig Mill Duet3 Control |

Taig /

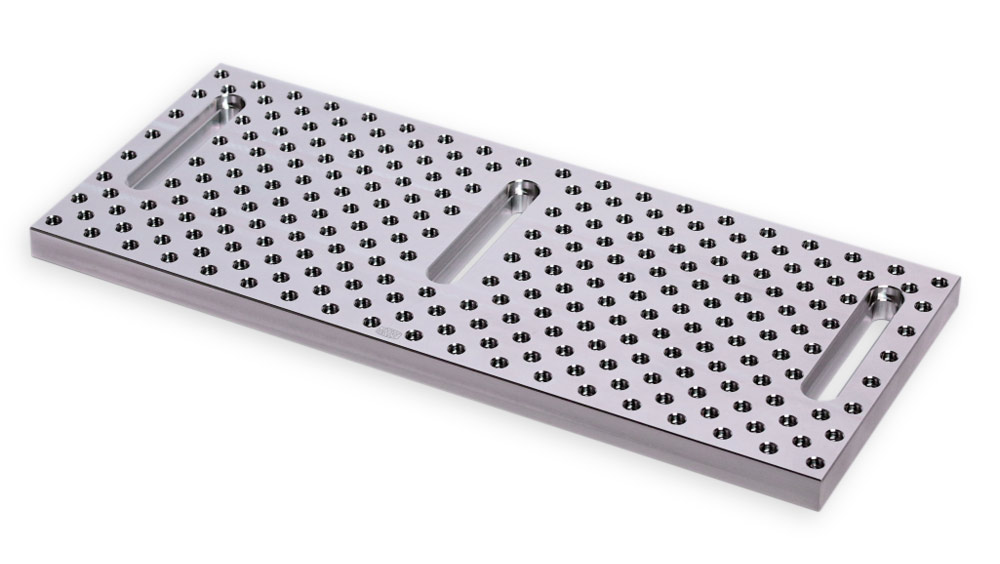

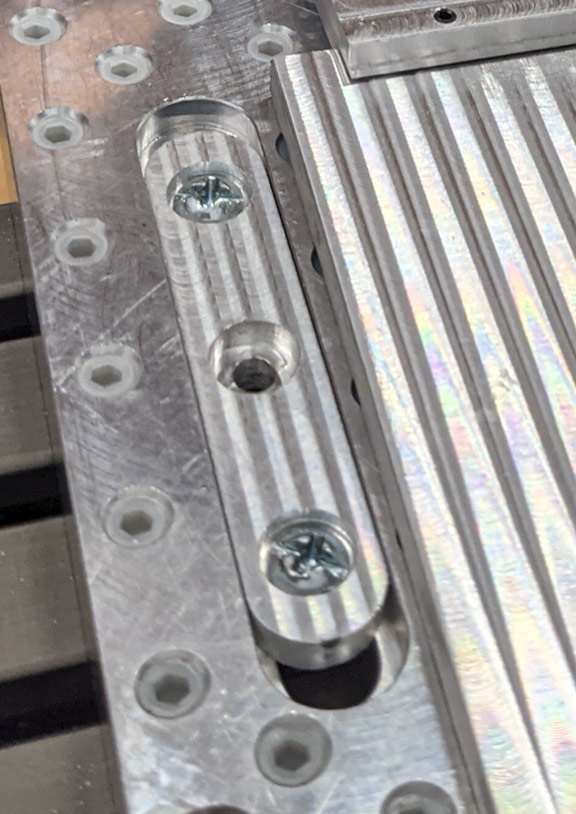

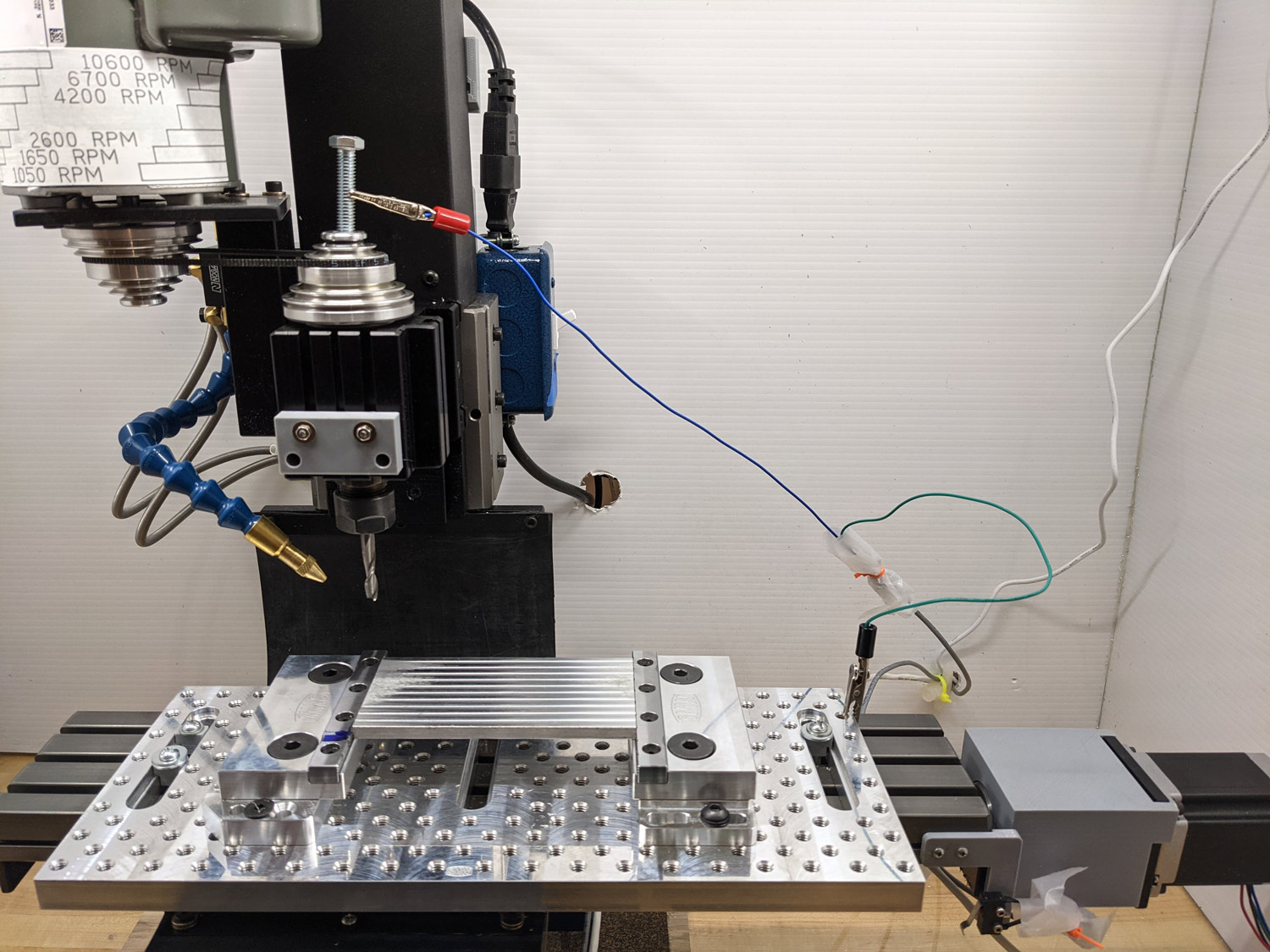

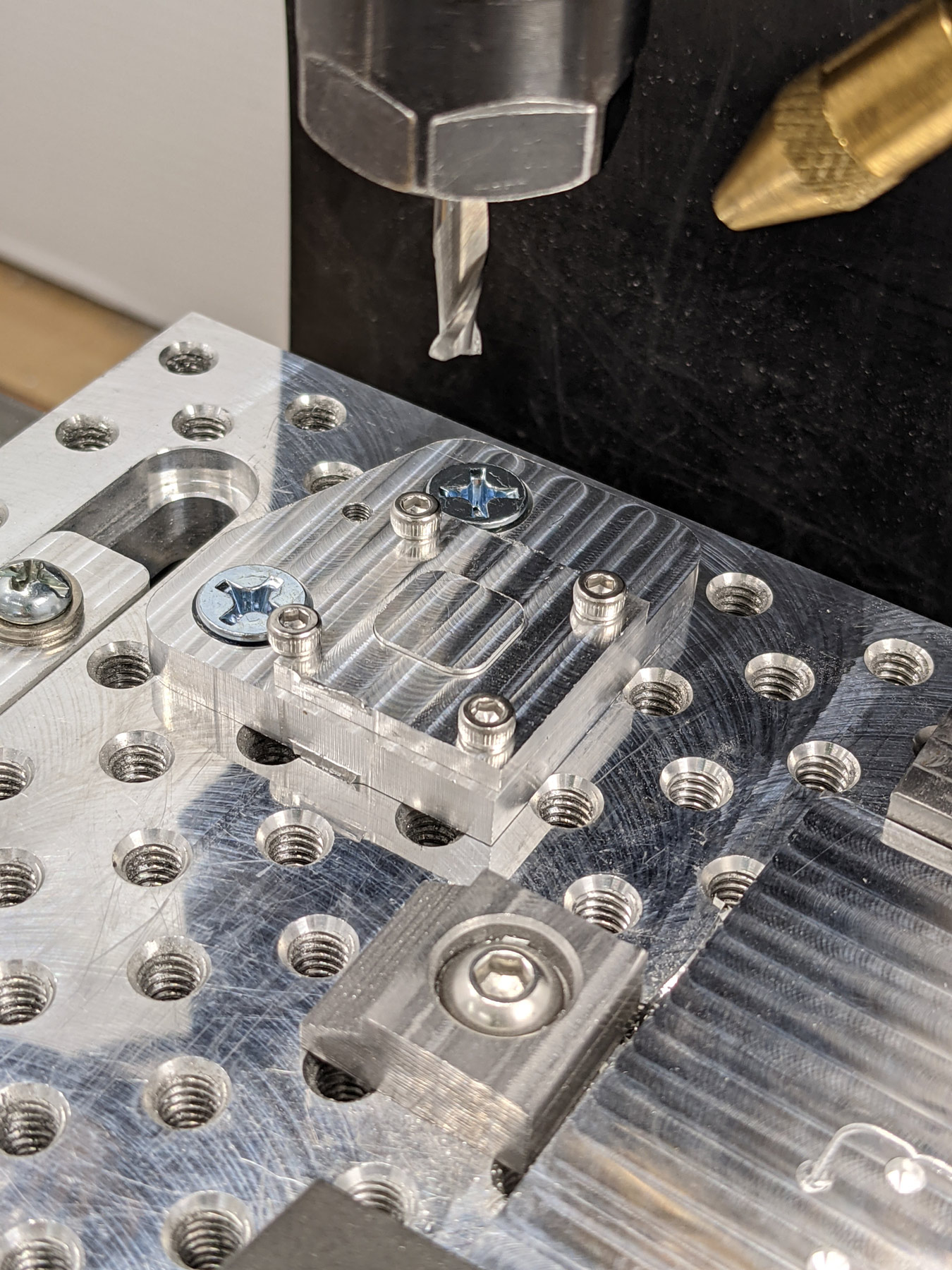

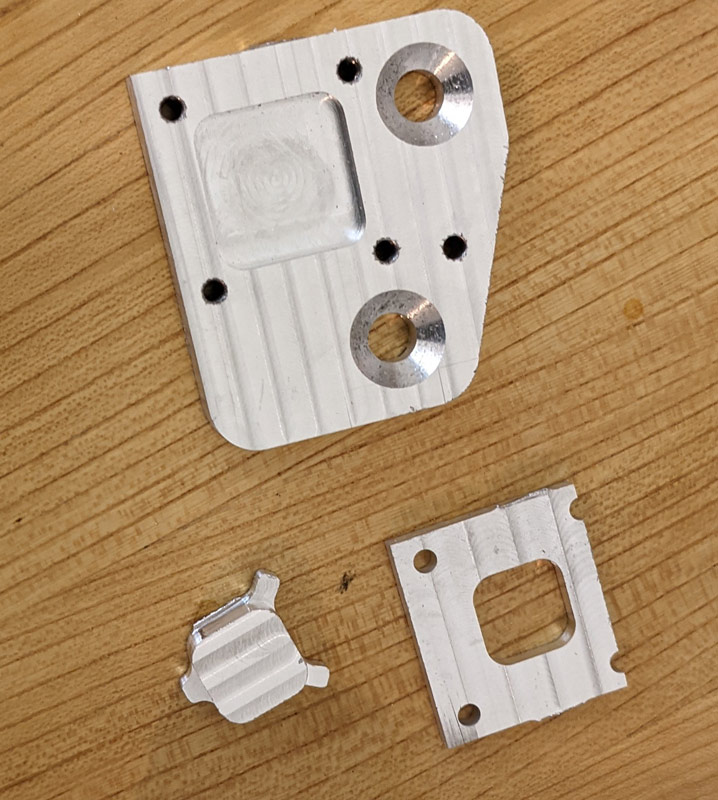

SaundersFixturePlateThe Saunders Machine Works Fixture PlateThe Saunders Machine Works company makes two of the most beloved Taig add-ons - a fixture plate and a vise. They have two fixture plates, a smaller 14"x6" for the older Taig mill and a larger 20"x6" for the newer Taig mill. Get the largest fixture plate your mill can handle. I got the smaller plate and regret it often. The larger plate lets you do two setups or a larger setup than the smaller plate and is far more functional.  There are a few things you'll want to do to make the plate the most useful.Screw InsertsThe 1/4" screw holes in the fixture plate are great but when you mill the shavings fall in the holes and block screws. I use plastic screw inserts (grub screws) that fit perfectly and stop metal shavings. Plastic Screw Inserts Plate ClampTo clamp the plate to the Taig bed I made aluminum plates that don't entirely fit the available space - so the plate can be moved up-down in the Y direction an inch for alignment.  Get the STL file here: Fixture Plate Earth GroundThe Taig mill uses anodized aluminum for the bed. This means the bed does not electrically connect to the frame and so you can ground the Saunders Fixture Plate and then use frame->plate connection to detect when the bit hits metal. This is a cheap but perfectly good positioning mechanism. So, the fixture plate has a sense pin applied to it while the mill frame is set to circuit ground. This provides mill bit touch sensing.  This image shows a very early test of the touch wiring. The plate sensor is now firmly attached using one of the fixture 1/4-20 screws and the mill ground is applied with a wire connected to the power switch frame. Z Touch SetterNo plate is complete without a fixed location to touch. This means a simple macro can move the head to the fixed X,Y location then slowly lower the head until it touches the touch-plate. This Z value is then referenced to the fixture plate top (Z zero) or the vise Z. This Z-setter uses two flat-head screws to reference the location and the touch-cube area has a little springiness to protect small mill bit tips.   |